Overview of Structural Steel

Structural steel is a crucial construction material, manufactured from shaped steel or cold-rolled steel, designed to withstand heavy loads in structural applications. With outstanding durability and high resistance to external forces, structural steel not only meets strength and safety requirements but also contributes to environmental sustainability due to its recyclability, helping to minimize the construction industry’s negative impact.

Structural steel products are fabricated into precise shapes and sizes according to the technical requirements of each project. Common processing methods include:

producing high-precision steel components with flexible applications across various construction types.

Diverse Applications of Structural Steel

Structural steel is not confined to a single sector but is widely used across multiple industries:

Classification of Structural Steel in Construction

In the construction sector, structural steel plays a vital role due to its superior load-bearing capacity and design flexibility. Based on shape and intended use, structural steel is categorized into different types, each possessing distinct characteristics tailored to specific construction demands.

V-Shaped Angle Steel

V-angle steel is a structural steel type with a “V”-shaped cross-section, featuring two perpendicular edges. It is widely utilized due to its strong connection capabilities and reinforcement efficiency in construction projects.

Additionally, V-angle steel is manufactured in various sizes and thicknesses, making it highly adaptable for small to large-scale projects, from residential to industrial applications. This variety not only facilitates selection but also offers outstanding economic efficiency.

Steel plate (flat surface)

Steel plates have a flat surface and are primarily used to enhance the load-bearing capacity of structural components. This type of steel is frequently employed in constructing floors, walls, or specialized structures requiring high durability. Steel plates are also easy to fabricate into complex components, making them suitable for various applications.

U-Shaped Steel

U-shaped steel consists of two parallel edges forming a “U” shape. With its high strength and excellent load-bearing capacity, this steel type is commonly used in load-bearing frames, support systems, and bridge construction.

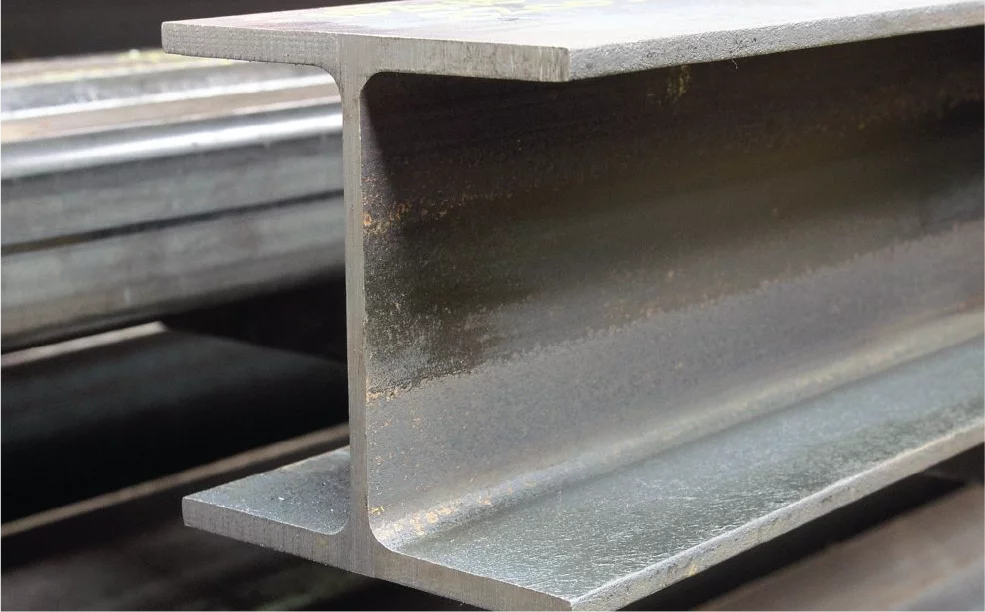

I-Beam / H-Beam Steel

I-beam and H-beam steel are two of the most commonly used structural steel types, sharing a similar cross-section but differing in size proportions.

- I-Beam Steel: Features smaller top and bottom flanges compared to the central web, optimizing axial load-bearing and bending resistance. It is widely applied in load-bearing beams, pre-engineered steel building frameworks, and both residential and industrial structures.

- H-Beam Steel: Designed with wide and evenly thick flanges, ensuring better load distribution than I-beams. With its superior load-bearing capacity, H-beam steel is often used in high-strength structures such as bridges, factories, and heavy-load frameworks.

Both types offer advantages such as lighter weight compared to reinforced concrete while maintaining high rigidity and durability, reducing structural load and lowering construction costs.

Rectangular Hollow Steel

Rectangular hollow steel sections are widely used in mechanical engineering and construction. With their excellent load-bearing capacity and balanced shape, they are frequently applied in structural frameworks, railings, and components requiring high precision.

Square Hollow Steel

Square hollow steel sections have a strong design, making them suitable for use as columns or pillars in various structures. While they are less frequently combined with other steel types, they are particularly effective in applications requiring high vertical load-bearing capacity.

Advantages and Disadvantages of Structural Steel

Below is a detailed analysis of the advantages and disadvantages of structural steel, based on its technical properties and practical applications in construction and industry:

| Criteria | Advantages | Disadvantages |

|---|---|---|

| Load-bearing Capacity |

|

|

| Durability and Service Life |

|

|

| Weight |

|

|

| Flexibility |

|

|

| Recyclability |

|

|

| Construction Time |

|

|

| Cost |

|

|

| Structural Stability |

|

|

| Aesthetic Appeal |

|

|

Structural steel is an ideal material for projects requiring durability, flexibility, and efficiency. However, to maximize its advantages and mitigate its disadvantages, it is essential to select the appropriate type of steel and implement effective maintenance and protection measures during use.

Advantages of Choosing Pebsteel

Global Experience and Reliability

With thousands of successful projects worldwide, Pebsteel has established a strong reputation in the structural steel industry. We take pride in being a trusted partner, ready to meet the most demanding requirements across sectors, from civil to industrial construction.

Commitment to Superior Quality

Pebsteel’s structural steel products not only comply with but exceed top international standards, including ASTM A36, SS490, A572 Grade 50, EN S275JR, JIS SS400, and S355JR. This ensures each product delivers exceptional load-bearing capacity and durability, making it ideal for technically demanding projects.

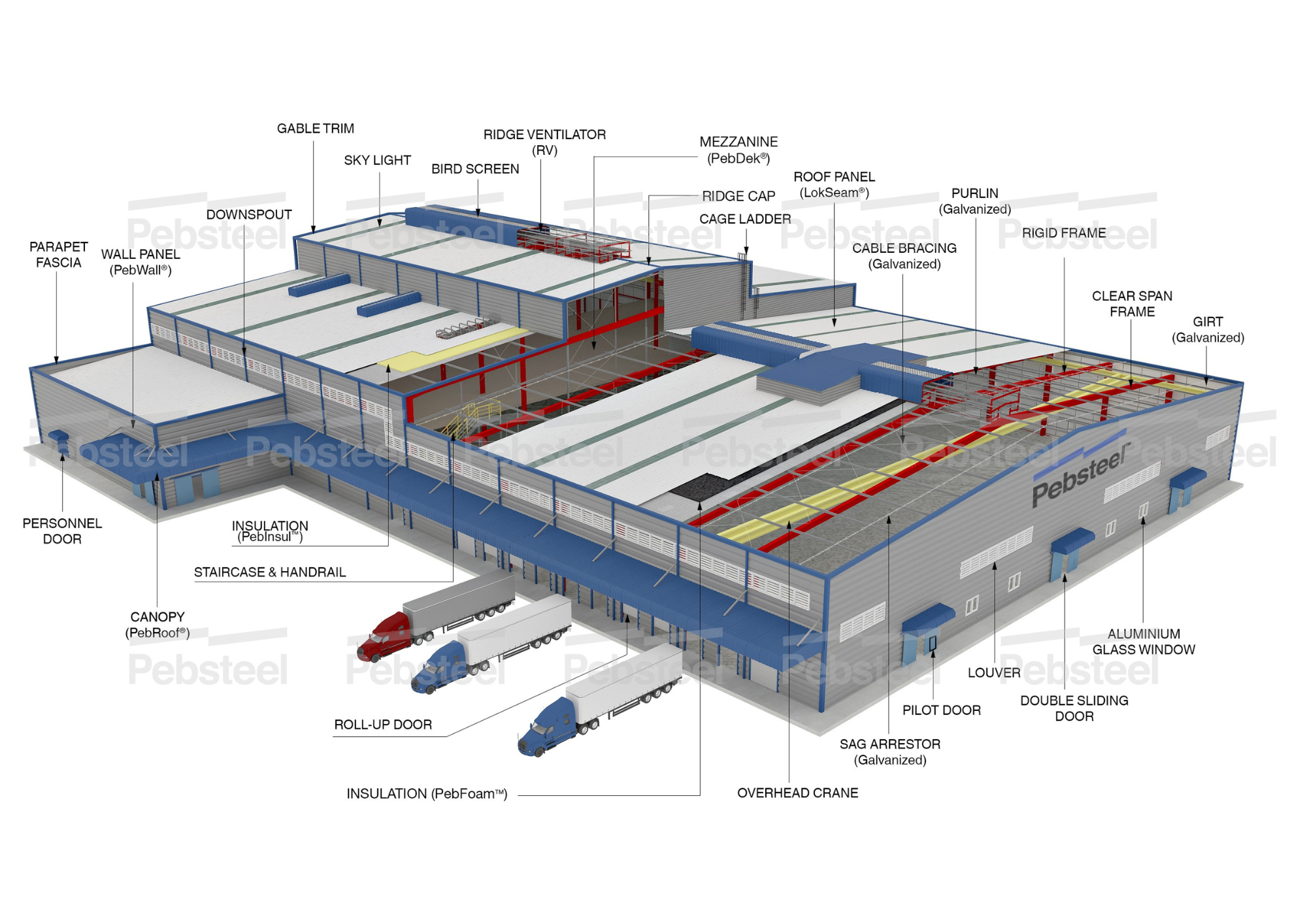

Comprehensive Solutions and End-to-End Support

We offer a full-service solution from design and manufacturing to installation, enabling clients to complete their projects in the most optimized manner. Pebsteel is not just a supplier but a reliable partner throughout the entire construction process.

For pre-designed projects based on standard rolled steel, the S.T.S. team will undertake:

Our execution team provides precise cost estimates and competitive bidding strategies, helping Pebsteel maintain its leadership in structural steel fabrication.

Uncompromising Reliability for Every Project

By utilizing high-quality steel standards, Pebsteel delivers products with superior durability and excellent load-bearing capacity, catering to projects of all sizes—from small-scale constructions to large-scale industrial developments. Every structural steel product we supply is committed to ensuring project stability, efficiency, and long-term sustainability.

With Pebsteel, you are not just selecting quality; you are choosing a strategic partner you can trust for all your construction needs. Let us turn your vision into reality with our comprehensive structural steel solutions. For inquiries or assistance, please contact us via email at marketing@pebsteel.com.vn or call +84 908 883531 for prompt support.

Relevant systems

-

PEB คือ โครงสร้างอาคารเหล็กสำเร็จรูประบบ Pre-Engineered Buildings วัสดุที่ใช้ในระบบ PEB มาจากผู้ผลิตชั้นนำและมีการจัดเตรียมไว้ล่วงหน้า โดยวัสดุทั้งหมดได้รับการรับรองตามมาตรฐาน ASTM และผ่านการควบคุมคุณภาพอย่างเคร่งครัด ความหลากหลายของวัสดุเหล่านี้ช่วยให้สามารถออกแบบโครงสร้างได้ตรงตามความต้องการของผู้ใช้งาน และรองรับการใช้งานในอาคารเกือบทุกประเภท