In steel structure, bolt connections are a component that plays an extremely important role. The use of bolt connections is to connect, assemble and link parts into block systems and truss frames. Bolts clamp the parts together according to the principle of friction between the nut and the threaded rings of the bolt. Let’s learn more about the structure, classification and arrangement of connecting bolts with Pebsteel through the following article!

1. The structure of bolt connections

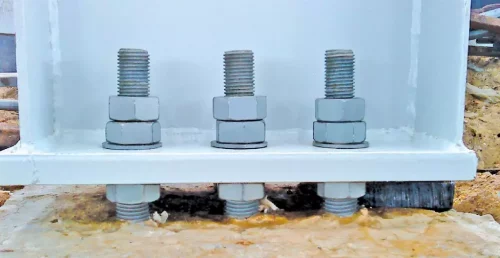

Bolts in structural steel usually have four main parts: the bolt body, the head, the nut, and the flat washer. These components come in many different sizes to suit a variety of uses during construction.

Read more: What is Synthetic Steel? Features and Classifications

1.1. The body of the bolt

- The bolt body is a circular section of steel with a diameter size (symbol: d) of 12 ÷ 48 mm. The most common type of bolt is in the range of d = 20 ÷ 30 mm.

- The inside diameter of the threaded part is denoted as do (do = 0.85d).

- For suspended threaded bolts (DIN 931): The length of the threaded part is denoted as lo (lo ≈ 2.5d). The length of the unthreaded part must be 2-3 mm less than the thickness of the steel plate when installing the through-bolt connection.

- For threaded bolts (DIN 933): The thread’s length is also the bolt’s length, denoted by l, with dimensions from 35 to 300 mm.

Read more: Details of Construction Process Of Industrial Factory

1.2. The head of the bolt

- The head of bolts is usually made into a hexagon with chamfered corners.

- The circumscribed diameter of the head is denoted as D (D = 1.7d).

- The thickness of the head is denoted as h (h = 0.6d).

- The diameter of the incircle of the head is denoted as S, usually an even number with S = 12, 14, 16, 18, …

1.3. The nut of the bolt

- Like the head of the bolt, the nut is usually hexagonal, drilled, and threaded like the body thread (equal thread pitch).

- The thickness of the nut is denoted as h, with h ≥ 0.6d.

Read more: Mechanical Factory Design Standards and Procedures

1.4. The flat washer of the bolt

- The flat washer is molded into a circular shape for the purpose of distributing the pressure of the nut evenly on the face of the basic steel structure.

- Dimensions D, do, lo and h are all specified based on the diameter of the bolt body (symbol: d), the larger d is, the larger the above dimensions are required.

The structure of bolts in steel structures consists of 4 parts

2. Types of connection bolts in steel structures

2.1. Rough bolt and normal bolt

This type of bolt is made from carbon steel by forging and stamping. The bolt body’s diameter is usually smaller than the hole diameter by about 2–3 mm because the accuracy is not high. Bolt holes are created by punching or drilling each plate separately. If the punching method is used, the hole surface will not be flat and the steel around the hole (2–3 mm) will be brittle due to cold hardening. Because of its low precision, the holes cannot fit completely when attaching the steel plates, so the bolts cannot come into close contact with the hole wall.

Rough and normal bolts are generally low in cost, fast in production, and easy to place in holes. However, the quality of these types of bolts is not high. During work (with sliding), it will be deformed quite a lot. Therefore, they should not be used when constructing essential projects. You should only use them when positioning components during assembly or when subjected to tensile.

2.2. Precision bolt

Precision bolts are made of carbon or low-alloy steel by the turning method with high precision. The diameter of the hole is not greater than the diameter of the bolt by more than 0.3mm. Every part of the bolt is required to be mechanically machined. There are 2 types of fine bolts: those that install into holes without clearance and those that generally install into holes with clearance. In particular, the first type of precision bolt has a diameter of the unthreaded part that is larger than the diameter of the threaded part. Thanks to the small gap between the body and the bolt hole, the fine bolt has a high bearing capacity and a tight connection, and the initial deformation of the connection is relatively small.

2.3. High-tension bolt

High-tension bolts are fabricated from alloy steel and then heated to the required tensile and tightening forces. This type of bolt is made of high-strength steel, so the nut can be tightened very tightly, which will cause the bolt body to be in tension and cause strong pressure on the connecting steel plates.

While under load, a large frictional force against the relative sliding between the contact surfaces of the steel plates is generated. Thus, the force transmitted from one component to another is mainly due to frictional forces.

High-strength bolts have good bearing capacity and joints are less deformed, so they are widely used and replace riveted connections in structures subject to heavy and dynamic loads.

After being fabricated, they are heat-treated, so the strength becomes very high. They have the ability to create extremely large tensile forces in the bolt body to squeeze the steel plates together and create friction, so their bearing capacity is very good.

Each type of bolt has its own advantages

2.4. Types of high-tension bolt connections

Shear connection

The shear resistance/shear force transmission capacity of a bolt connection is created by the friction force between the connecting steel plates due to the pressure of the bolt. In a shear connection, the force is perpendicular to the bolt body, the steel plates turn into pressed holes, and the bolt body is sheared.

The shear connection has the advantage of being simple; the construction process is easy but still bears a very strong force. However, it has the disadvantage of easy slipping because the hole is larger than the bolt body.

With this type of connection, high-strength bolts do not need to be tightened too tightly or too forcefully. Therefore, using the tightening force created by the standard wrench is enough.

Non-slip connection

This connection also bears the force perpendicular to the bolt like the shear connection, however, the bolt is tightened as much as possible to create friction between the steel plates, preventing slipping. This connection is applied to crane beams, bridges, dynamic load-bearing structures, etc. According to design regulations, high-tension bolts in non-slip connections must be tightened to the required tension.

Tensile bolt connection

This is a type of connection where the force is along the direction of the bolt (for example: house frame beam connection, flange connection). The TCVN standard does not have requirements on how to tighten tension bolts. However, according to the standards of American, European, Australian countries, … bolts must be tightened with a force greater than the force they will bear when working under load to prevent the flanges from separating.

4. The arrangement of bolts in steel structures

When arranging bolt connections in steel structures, paying attention to the distance between bolts is necessary. If the bolts are spaced too close together, the connecting steel plate has a high risk of being torn off. Meanwhile, if the bolts are arranged too far apart, it will lead to a waste of materials, the connection is not tight and easy to rust; in addition, the steel plate between the two bolts is not stable while under compression. Therefore, the bolts should be arranged at a distance from each other to make the connection compact but still ensure the necessary bearing capacity as well as being material-saving.

There are 3 layouts to arrange bolts:

- Parallel layout

- Staggered layout

- Arrangement of bolts for section shaped steel: Based on the size of each type of section steel, the position of bolt rows is specified. For angle steel, there will be 2 cases: If the width b < 100 mm, 1 row of bolts will be arranged, and if the width b > 100 mm, 2 rows of bolts will be arranged.

5. Conclusion

Above is information about bolt connections in steel structures such as the structure and types of bolts in steel structures. If you are looking for comprehensive solutions for pre-engineered steel buildings and steel structures, please contact Pebsteel via email at thaisales@pebsteel.com or phone number +66 2258 4639-41 for advice.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.