Alloy steel, a versatile material, is widely used in construction due to its ability to meet various requirements such as lightweight, high strength, and good load-bearing capacity. In the current market, there are various types of steel, including shaped steel, alloy steel, galvanized steel, etc. In this article, let’s explore what alloy steel is, along with its characteristics and applications with Pebsteel!

What is alloy steel?

Alloy steel is a type of steel primarily composed of iron and carbon, with additional chemical elements mixed in such as copper, manganese, nickel, etc. The total amount of these added elements typically ranges from 1.0% to 50% of the total weight of the steel mixture, aiming to enhance the properties of the final product. These improvements may include resistance to oxidation, elasticity, ductility, and strength of the steel.

Below are some common alloying elements:

- Manganese: This element is added to adjust heat treatment requirements. Typically, steel needs to be rapidly cooled from high temperatures to incredibly low temperatures to harden. However, the challenge is that excessively fast cooling increases the risk of cracking. Meanwhile, manganese allows for a slower cooling rate, thereby minimizing the risk of fracture.

- Chromium: Steels with chromium content exceeding 11% are called stainless steel. The addition of chromium enhances the steel’s resistance to corrosion, while significantly affecting other metal properties such as hardness, strength, and tempering.

- Molybdenum: This element is added to increase the ductility and hardness at high temperatures. Additionally, molybdenum improves machinability, corrosion resistance, and enhances the influence of other alloying elements.

- Vanadium: This element helps improve hardness, abrasion resistance, and impact resistance. Vanadium also limits the growth of metal grains, allowing for quenching at higher temperatures.

Classification of alloy steel

Generally, alloy steel is divided into the following two types:

- High-alloy steel: This type of alloy steel contains elements with a concentration greater than 10% of the total steel mass.

- Low-alloy steel: Typically, elements such as chromnium, silicon, manganese, and others are added to create low-alloy steel. The concentration of these elements does not exceed 10%. Low-alloy steel is a common and widely used type in today’s market.

Additionally, based on its applications, alloy steel is classified into the following three types:

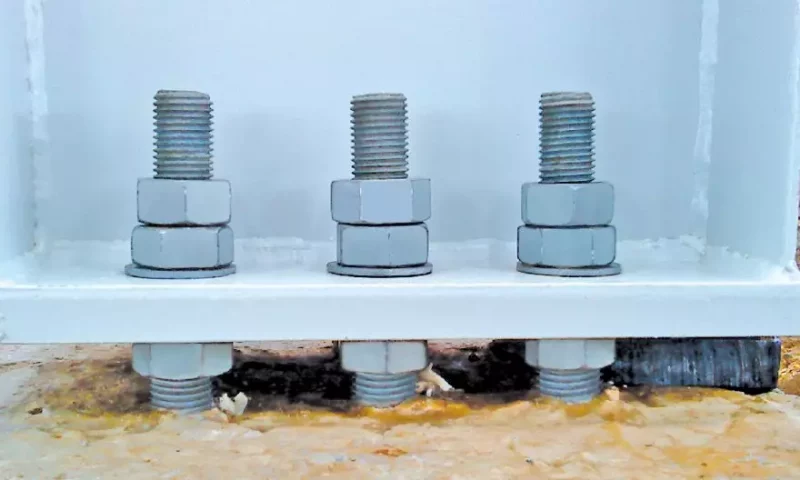

- Steel structure: This type of steel is used for manufacturing machine parts and metal structures. The specific requirements for this steel group include flexibility and high strength. Typically, this type of steel has a low to medium carbon content, belonging to the category of low-alloy steel.

- Alloy tool steel: This is a high-quality steel used in the production of cutting tools, stamping dies, and measuring instruments. The requirements for these steels include high hardness and corrosion resistance. Generally, this group has a medium to high carbon content. Common steel grades such as SKD61 and SKD11 often belong to this category.

- Special alloy steel: This group comprises steels with unique chemical and physical properties. The added elements have a high content, belonging to the group of high alloy steel group

Characteristics of alloy steel

Let’s analyze the characteristics of alloy steel based on the following criteria:

- Mechanical properties: Alloy steel typically exhibits significantly higher strength than carbon steel, especially evident after the quenching and tempering processes.

- Heat resistance: Alloy steel maintains high mechanical properties in a hardened state at temperatures exceeding 200 degrees Celsius. To achieve this, the steel needs to be alloyed by adding elements with relatively high concentrations.

- Physical and chemical properties: Alloy steel is corrosion-resistant and possesses the ability to resist corrosion. Especially, it exhibits exceptional expansibility when temperatures change, etc.

Advantages and applications of alloy steel in construction

Alloy steel has several outstanding advantages compared to many other types of steel, such as:

- Excellent corrosion resistance

- High load-bearing capacity

- High melting temperature

Due to its numerous advantageous properties, alloy steel is preferred by investors in various manufacturing sectors, including:

- Construction projects

- Manufacturing machinery, automotive components, etc.

- Producing various types of shafts (forged rolls, motor shafts, etc.)

- Manufacturing gears.

Conclusion

The above provides details about what alloy steel is, along with some of its characteristics and applications. Please contact Pebsteel. Press here

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.