For all types of construction, the floor is an extremely vital component, serving as the primary load-bearing structure for the entire building.

Currently, many investors opt for the double-layered floor steel structure due to its high durability and excellent load-bearing capacity. However, if they are not arranged according to the correct standards, the floor structures will not achieve their full efficiency in use. Let’s explore the definition, structure, and how to arrange double-layer steel floors correctly with Pebsteel in the article below.

What is a double-layer steel floor?

The double-layer steel floor is the main load-bearing structure, where beams and columns play a supporting role in the steel structure floor. Beams are responsible for transmitting loads to columns, while columns undertake the task of transferring the received loads down to the foundation of the structure. Designing with two layers supports the effective distribution of loads and enhances flexibility during the construction process for various types of construction.

What should be selected between the one-layer and double-layer steel floor arrangement?

Typically, the decision to choose between one-layer and double-layer steel floor structures is determined by the construction load and the construction site conditions. For instance, when constructing a simple four-level building, opting for a 1-layer steel floor structure is still a feasible choice.

However, for large-scale projects with high loads, arranging double-layer steel floors has become crucial. Double-layer steel floors offer advantages such as robust load-bearing capacity, high reliability, lightweight construction, and the ability to span large distances. Additionally, these structures exhibit high flexibility during transportation and installation, making them an ideal choice for highly industrialized projects that demand rapid construction timelines.

How to arrange double-layer steel floors step-by-step

Here are detailed steps for double-layer steel floor structure arrangement according to the standard:

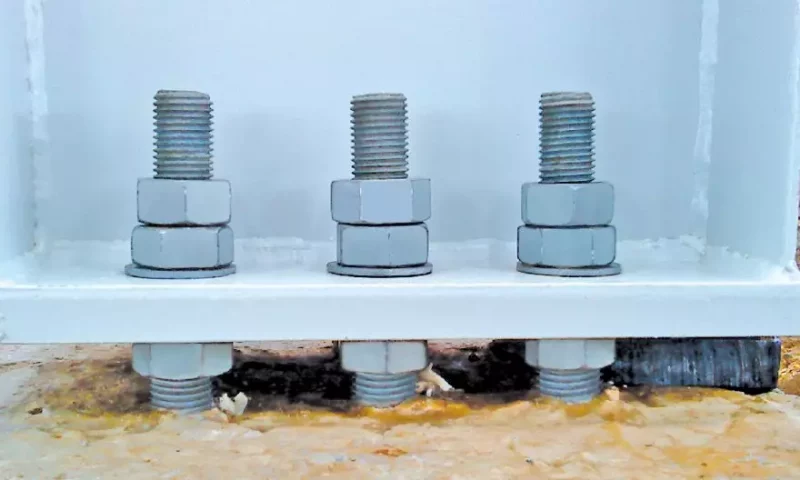

•Step 1: Firstly, the process starts by placing the steel underneath, with the beam following the first short edge. Next, the lower-layer steel bars are placed along the long edge. The length of the stirrup bars is calculated from the edge of the beam and then hooked onto other bars. Additionally, marking on the main beam bars with ink or erasable pen before placing the steel strip helps easily determine the position.

• Step 2: Following step 1, the workers proceed to install negative moment steel bars. The length of these bars is measured from the beam’s edge to the end of the steel length. This length needs to meet specified dimensions (e.g., 35D).

• Step 3: After completing the installation of negative moment steel bars, workers will use steel structure to secure the frame. Typically, bars with a diameter of Ø8 and quality grades A200 or A300 are used.

• Step 4: To protect the concrete floor layer, workers will use supporting blocks, such as granite or stone 1 2, with a thickness of about 2.5 – 3cm.

Here are some notes when arranging double-layer steel floors:

• At the location where two stirrup bars overlap, it is mandatory to place a sufficient quantity of steel, and no omission is permissible. During this phase, the short-edge steel bars will be positioned on top.

• For stirrup caps, it is advisable not to use Ø6 or Ø8 but rather Ø10. This is because when pouring concrete material and subjected to human footsteps, it can reduce the effective height of the stirrup, leading to a risk of subsidence.

Conclusion

Hoping that the recent article has provided the comprehensive answer to the question of “What is factory aperture?” and additional useful information. Please contact Pebsteel. Press here

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.