Single-girder overhead cranes are widely used in factories and workshops today. These essential equipments are used for lifting and lowering goods of varying weights. Let’s explore the structure of a single-girder overhead crane and its basic technical specifications with Pebsteel in the following article.

What is a single-girder overhead crane?

A single-girder overhead crane, also known as a single-girder bridge crane, is a common type of crane with its simple structure and cost-effectiveness. It is designed to lift, lower, and move loads within areas such as workshops, factories, and storage yards. This equipment is a suitable choice for medium-scale operating environments.

The main structure of the girder in a single-girder overhead crane is diverse, and it can be a hot-rolled steel I-beams, cast H-beams, or a combination of welded beams, etc., as long as it ensures that the girder can withstand the load as a single entity.

Understanding the structure of single-girder overhead crane

Main girder

The single-girder overhead crane utilizes the main girder in the form of I-beam, H-beam, or welded box girder to resist torsion. The main girder is typically made from materials like SS400, Q345B, or Q235. In the case of a box girder, it is internally equipped with partitions and stiffeners, securely welded using specialized equipment.

The block and tackle travel limit is directly welded to the moving edge of the bottom plate and installed on both sides of the main girder.

Block and tackle – Electric winch

The block and tackle play a crucial role in ensuring the lifting, lowering, and moving loads within the factories. This equipment is operated by electric motors, with a lifting capacity ranging from 1 to 500 tons. Therefore, it is widely used in industrial manufacturing factories for loading and unloading of goods.

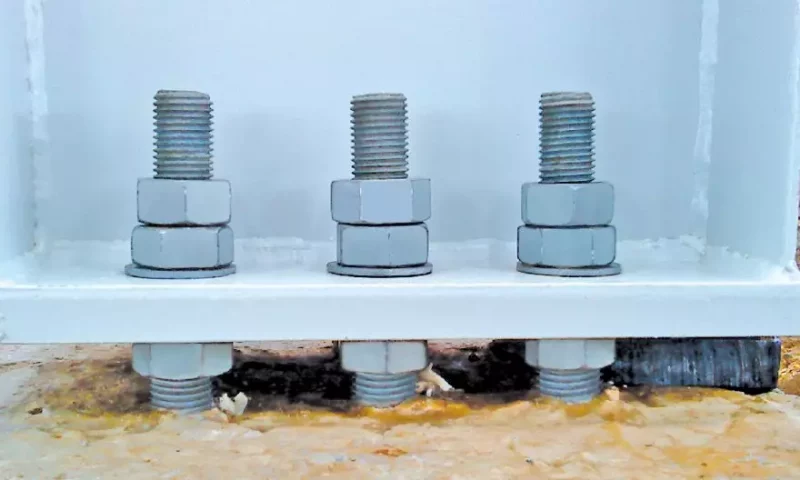

Boundary beam

The boundary beam is an essential component enabling the main beam to move from the beginning to the end of the factories. The boundary beam consists of two beam bars, fabricated from plate steel, I-beams, or H-beams, which are then mounted on the wheel assembly. Each end carriage is equipped with a moving motor, where the wheel axle supports and motor flanges are processed on CNC machines to ensure the precise alignment of wheels and gears. The boundary beam is connected to the main beam with high-strength bolts at the corresponding torsional moments.

Wheels

The wheels will move along the rail, supported by lifting ball-bearings and lubricated with oil throughout the operation. The wheel body is fabricated from high-strength C45 steel using taper turning methods, then undergoing a surface hardening process to resist abrasion. In addition, the wheel bearings are designed for easy installation and do not require special maintenance.

Electrical Cabinet

The electrical cabinet is responsible for controlling the functions of both the block and tackle and the overhead crane. The crane’s electrical control cabinet includes a frequency inverter, contactor, circuit breaker, relay, discharge resistor, phase loss protection and other components. These parts are connected and housed inside a protective casing.

Horizontal and vertical power lines

The power line system supplies power to the block and tackle and the overhead crane. In this system, the horizontal power line for the hoist commonly uses a deep groove electrical system, a C-rail electrical system, and a flat flexible cable electrical system. Meanwhile, the vertical power line for the single-girder overhead crane typically uses a 3P or 4P conductor bar.

Safety equipments (optional)

Safety equipment plays a crucial role in preventing and minimizing risks during the operation of the overhead crane. Safety equipment includes limit switches, overload switches, collision switches, emergency switches, alarms, warning lights, and various other devices.

Wired pendant control, remote control

The wired pendant control is used to command the movements of the overhead crane, including upward, downward, eastward, westward, southward, and northward motions. The control device can have one or multiple speeds, depending on the specific type of overhead crane.

Basic specifications of the single-girder overhead crane

Here are some reference technical specifications for a single-girder overhead crane:

- Standard lifting capacity: 1 – 20 tons

- Span: 3 – 30m

- Lifting height: 2 – 20m

- Travel length: Unlimited

Conclusion

These are the details about the structure of the single-girder overhead crane and its basic reference technical specifications. Please contact Pebsteel. Press here

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.