Home / Solutions / Products / Sheeting components / Materials /

AluPeb®

AluPeb® panel is the most innovative, super durable, and environmentally friendly product to provide superb color fastness and corrosion resistance despite severe environmental conditions.

Product Features

- Environmentally friendly product (Chromate-free)

- Good heat resistance & reflectance

- Superb color fastness and corrosion resistance

- Long-term durability.

Technical Specifications

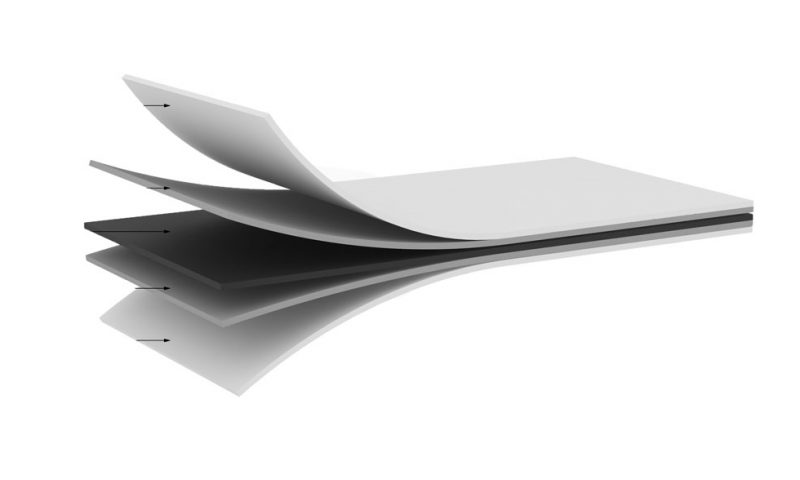

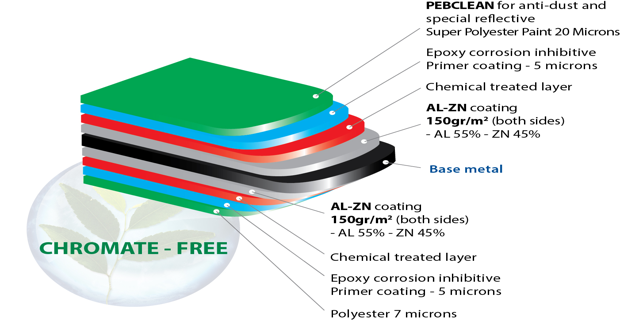

AluPeb® consists of 5 main layers:

- Top coat: Super Polyester Paint 20 Microns which provides an anti-dust and special reflective functionalities – PebClean, also maintains the color appearance and a barrier film to enhance long-term durability.

- Primer coat: 5-micron Epoxy corrosion inhibitive primer coating to prevent undercutting of paint and enhance corrosion resistance.

- Chemical treated layer: to provide good adhesion and enhance corrosion resistance.

- Zinc-Alum (Zinc-Aluminum) steel substrate: Zinc-Aluminum coated layer 150gr/m² (that consists of 55% Al-Zn 43.4% – Si 1.6%) which is chromate-free and strongly corrosion resistant despite severe environmental conditions.

- Base metal: JIS G3322 CGLC440, or equivalent.

Superior backside coating of 12 microns.

Specialty of Zinc & Al-Zn

The Zinc has a self physical property called Cathodic reaction. Whenever any cut happens in the material the adjacent side of the zinc reacts with the external environment (air, rainwater) that forms the ZnO₂ layer on the cut edges to protect the base steel against oxidation (self-healing property).

The Aluminum has good barrier protection while the Zinc has good self-healing property. Therefore, the combination of these materials, which is Zinc-Aluminum coated layer 150gr/m², provides optimum corrosion resistance for sheeting panels.